Production program

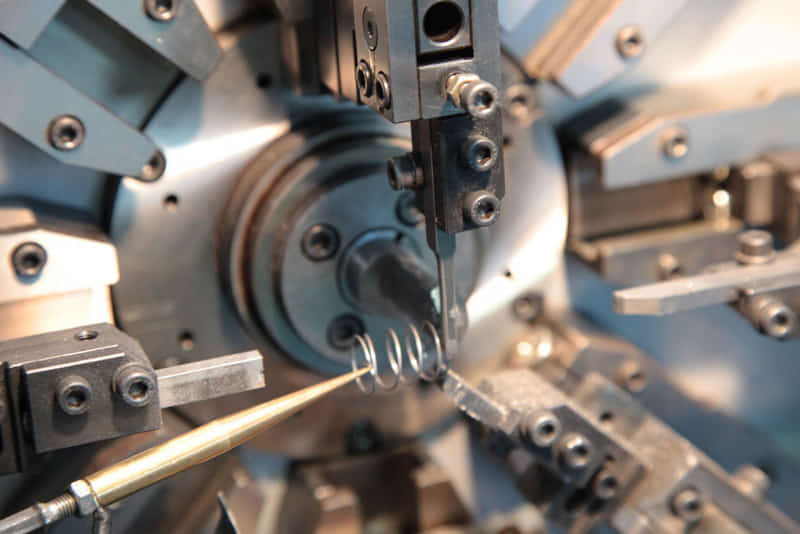

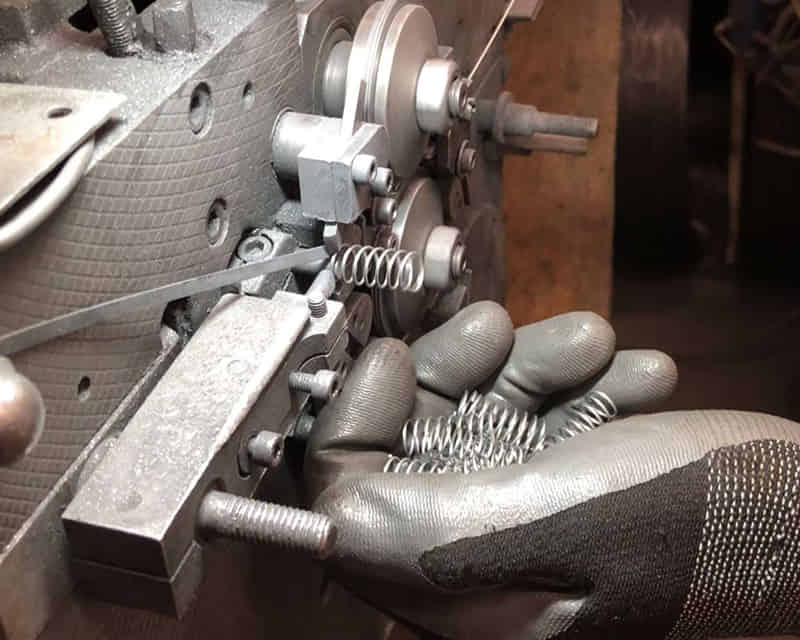

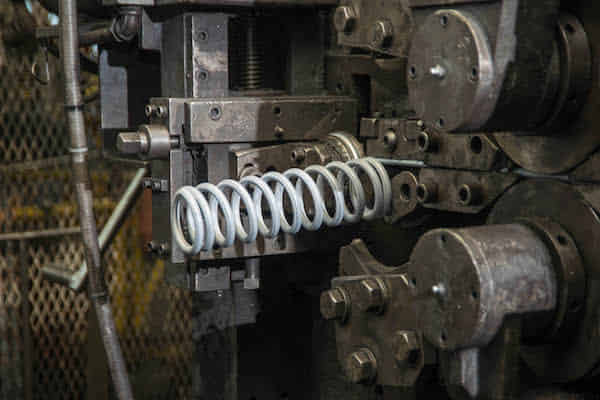

Production of all types of springs with wire thickness from 0.2 to 25 millimeters

APPLICABLE MATERIALS:

- Applicable materials for making springs

- patented steel wire according to DIN 17223

- chrome-nickel wire according to DIN 17224 and 17225

- hardened copper alloys according to DIN 17677

Thermal treatment of springs:

- tempering of springs

- Normalization of springs

- Spring stabilization

Surface protection:

- Zinc plating of springs

- Burnishing of springs

- Nickel plating of springs

- Plasticization of springs

- Painting springs

Types of springs by assortment:

- COMPRESSION springs standard DIN 2095 (Compression springs - compression)

- EXTENSIVE springs standard DIN 2097 (Extension springs - traction)

- TORSION springs standard DIN 2088 (Torsion springs)

- LEAF AND DISC springs standard DIN 2093

- SPRING FUSES AND BRACELETS

- SPECIAL springs

Types of springs by purpose:

- Springs for the mechanical industry

- Springs for the electrical industry

- Springs for the furniture industry

- Springs for the construction machinery industry

- Springs for agricultural machines

- Springs for the shipbuilding industry

- Springs for the paper, cardboard and pulp industry

- Springs for the chemical industry

- Springs for the rubber industry

- Springs for the tobacco industry

- Springs for the wood industry

- Springs for the shoe industry

- Springs for the leather industry

- Springs for the water and juice industry

- Springs for the textile industry

- Springs for the military industry

- Springs for the meat products and processing industry

- Springs for the food industry

- Springs for the construction industry

- Springs for the pharmaceutical industry

- Springs for the metalworking industry

ABOUT US

The company "Opruga Plus" was founded in 1994. From the very beginning, we have been engaged in the design and production of various types of springs for various purposes.

Through dedication and work over the years, we have learned a lot about design, manufacturing and precision. We offer assistance with technical guidelines for proper design and implementation. Our main goal is to make a top quality product.

Following modern trends in the production of springs, we are ready to respond and respond to any task. Also, with quality service, respect for the deadlines and requests of the client, we meet the needs of both business and individual users in the right way.

ORDER BOOK

We make springs based on a sketch, drawing or provided sample.

When defining measurements, we provide assistance in choosing the right measurements for the necessary spring. Also, you should take into account the place where the spring is installed (whether it is exposed to some chemical agents, water or high temperatures), the force acting on it, the number of cycles that the spring performs in a given period of time.

Based on the previously mentioned parameters, we can determine the right material for making the spring.

You can see the applicable materials for making springs here.

By defining and considering the place of installation of the spring, we can prevent possible deformations that occur as a result of work, adapt to the installation measures and get the spring to work properly, for the sake of a longer duration. Our goal is that with our help you get a quality product that will have a long-term work cycle.

To create an online order, it is necessary to define the following elements:

The thickness of the spring wire

The outer diameter of the spring

Number of turns of the spring

Spring length

The amount of springs

Spring ends (ground or unground)

PRODUCT CATALOG

You can view our System Springs and Disc Springs in standard dimensions.

When ordering springs, the easiest way is to specify the product code found in the right column of the product. If you need help or some guidance for choosing the right spring, feel free to contact us.

Contact

Address

Aerodromska bb37240 Trstenik, Serbia

Phone

+381 66 229 611

+381 62 22 69 11

+381 37 716 332

info@opruga.rs

oprugatrstenik@yahoo.com